MARTIN® PKL® Interval Impactors generate individual blows similar to a hammer. The impact provides very high acceleration, the exact force required to move sticky or clinging materials from storage vessel walls. The impacts per minute are variable between 10 and 60, without the use of a timing device.

The superb controllability of the MARTIN® PKL® Interval Impactors ensures just the right force to do the job, reducing noise, energy costs and bin damage.

Some Models Available in Stainless Steel

Available with a Revolutionary Mounting Option

You can pair select models of this product with our incredible

adhesive mounting system that makes mounting a breeze. No welding, no drilling, no bolting, no intrusion and no downtime!

Features

High Acceleration

The impact provided by MARTIN® PKL® Interval Impactors moves material that will not respond to rotary vibration.

Extremely Low Energy Consumption

The low operating frequency combined with the “air-against-spring” design translates to extremely low energy costs.

Precise Control

Adjust the number of impacts to provide the right force to do the job–no wasted energy, no bin or hopper damage. This is the most controllable vibrator available.

Best Uses

- Removing sticky materials from bin walls.

- Cleaning dusty residue from surfaces.

- Breaking “bridged” material.

- Great for spray dryers, pipes and dust collectors!

Additional Specifications

- Air Pressure Range: 45-115 psi.

- Operating Temperature: Max. 250°. High-temp models 320°F.

- Air Preparation: 5-micron filter, pressure regulator & lubricator.

- Force (maximum): 120-1,700 in-lbs

- Warranty: 3 years when operated within recommendations

Applications

High-Temperature Solution

MARTIN® PKL® 2100 Impactor

An insulated ash hopper is equipped with MARTIN® PKL® 2100 High-Temperature Units. The ash hoppers are impacted; the ash falls to the bottom and is removed via a screw conveyor. The units are spaced away from the heat source with stand-off brackets.

Powder Build-Up Solution

MARTIN® PKL® 740 Impactor

Fine powder was building up on the walls of a pipe leading to a bagging machine. The reduced flow limited and sometimes stopped production. A MARTIN® PKL® 740 Impactor was installed on the pipe elbow. The MARTIN® PKL® 740 Unit impacts one time, when the bagging machine calls for material. Problem solved.

Eliminate Shut-Down & Man Hours

Problem:

Fly ash was building up on the walls in a trash-to-energy facility. The build-up became so severe that the incinerator had to be shut down and men sent in to remove it.

Solution:

MARTIN® PKL® 5000 Impactors were installed eliminating the problem. The units were installed in several locations around the structure.

Portable Applications

MARTIN® PKL® Series Vibrators are available as MARTIN® Vac-Mount™ units, perfect for portable applications.

PKL® 5000 Single Impactors

MARTIN® PKL® 5000 Single Impactors used to clean heat exchange tubes.

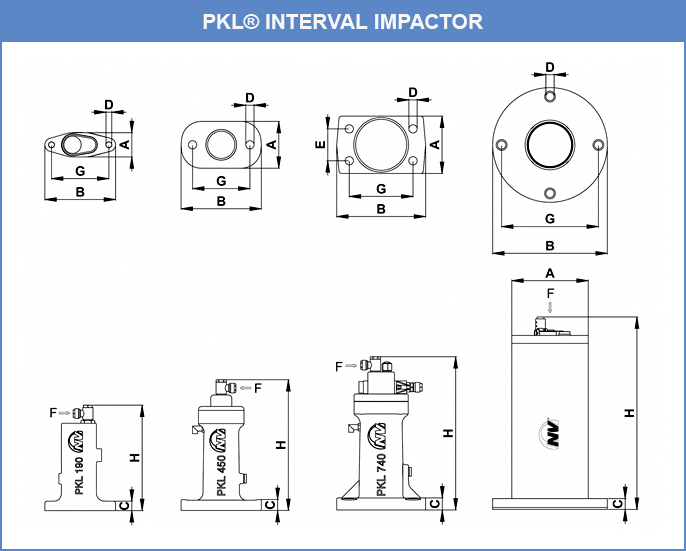

PKL® Interval Impactors Spec Sheet

Download

Gallery

See the MARTIN® PKL® Interval Impactors in action!

Only Cavemen Bang On Bins!

Equipment has evolved since the caveman days of banging on feeders and hoppers to keep product moving. The MARTIN® PKL® Interval Impactor delivers individual blows like a hammer with between 120 and 1,700 pounds of force, depending on your needs. Best of all, it's safer for your workers and doesn't damage equipment.

Best uses and case studies for MARTIN® PKL® Interval Impactors

-

Paprika Powder Retaining Moisture

A customer in food manufacturing was using paprika powder as an ingredient, which required emptying it from a 56-liter silo and dosing with a DosyPack. Due to the hygroscopic qualities of paprika powder, the material would frequently retain moisture, causing the material to form lumps inside the silo, entailing an accurate dosing result. Flow was further restricted by the formation of ratholes or tubes inside the material. Workers then had to manually strike the silo with a hammer to keep the material flowing, risking worker safety and potential damage to the equipment. The inefficient flow also led to substantial downtime.

The customer installed a MARTIN® PKL® Pneumatic Impactor to the silo, which delivers individual strokes to the side of the silo, substantially improving the flow of material and allowing it to empty thoroughly. Also, the DosyPack was equipped with a MARTIN® NTS™ 250 Pneumatic Linear Vibrator, which moves material evenly and enables highly accurate dosing of the paprika.

-

Bulk Solid Chemical Bridging and Sticking

A customer in the chemical manufacturing industry, working with a 400-liter stainless steel hopper containing a fine bulk solid powder, faced significant challenges with flow, which led to inefficient emptying of the container. Build-up that included bridging, ratholing and material sticking to the interior sides was a constant problem, resulting in potential undesirable mixing between products and batches. Manual methods that included striking the sides of the hopper with a mallet were ineffective and increased the risk of injury to workers, as well as damage to the equipment.

To solve the problem, the customer installed a MARTIN® PKL® Interval Impactor and a sequence control system to the hopper. During the emptying process, the PKL impactor delivers three strokes to the hopper, improving flow, emptying it thoroughly and allowing it to be filled with a new product. To keep the material from bridging on an ongoing basis, the sequence control system is set to trigger the impactor so that it delivers continuous strokes to the hopper for five seconds at five-minute intervals.

As a result of the case_study of our products, the customer was successful in optimizing flow and preventing bridging within the hopper. This eliminated the possibility of undesirable mixing between products and batches, while enhancing overall efficiency and worker safety.

-

Combustion Gas Fuel in a Heat Exchanger

A power plant was experiencing decreased efficiency with a heat exchanger because the combustion gas fuel was creating ash deposits on the tubes. The ash buildup was acting as an insulator, obstructing the transfer of heat energy through the tube walls.

The company installed a MARTIN® PKL® Pneumatic Impactor onto the heat exchanger along with an AP 116 timer that delivers a single stroke at 30-second intervals. The regular impacts prevent the ash from building up on the tubes, thus improving the transfer of heat energy through the tube walls. This has substantially increased the efficiency and service time of the equipment, while also improving profitability by reducing the amount of labor required for periodic regular cleaning.

-

Eliminating Hammering to Avoid Bridging

A customer in the chemical manufacturing industry was experiencing substantial bridging and buildup of product inside its hoppers during emptying, especially when working with fine powders and substances that tended to retain slight amounts of moisture. This meant that the only way to achieve thorough emptying was to strike the sides of the hopper with a hammer or mallet, risking worker safety and potentially causing damage to the hopper.

The customer installed a MARTIN® PKL® Interval Impactor powered by compressed air and fitted with an automation control. By delivering continuous, measured strikes to the side of the hopper with a piston, the pneumatic impactor made it possible to completely empty the product from the hopper.