Transferring products, ranging from powders to loose items, into containers for shipping or retail packaging can be a slow, labor-intensive process, especially when it involves hand-scooping bulk solids. The repetitive motion is slow and accuracy suffers if the containers need to be filled to specific weights or volumes, such as in a small food packaging operation.

Transferring products, ranging from powders to loose items, into containers for shipping or retail packaging can be a slow, labor-intensive process, especially when it involves hand-scooping bulk solids. The repetitive motion is slow and accuracy suffers if the containers need to be filled to specific weights or volumes, such as in a small food packaging operation.

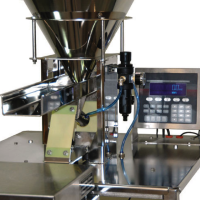

A hopper or feeder assembly that incorporates vibration to move product along makes the semi-automatic filling process more efficient by minimizing the need for handling product manually. Additionally, the risk of damaging the product is minimal because vibration is a gentler way to move materials. Plus, because vibration settings are adjustable, the throughput is highly accurate. By equipping the feeder with an electronic scale, feeding product into containers by weight becomes a more precise process.

At Martin® Vibration Systems, we have hundreds of products that fulfill a wide range of needs and budget requirements. For a feeding operation, equipment is available with the vibration assembly built in. Or, an industrial vibrator can be mounted to your existing equipment. We’re happy to discuss your operation’s processes and help you determine which product will increase your throughput and save you money. Just give us a call at 1-888-920-1933 or send a message to our Engineering/Application Department to connect with us.